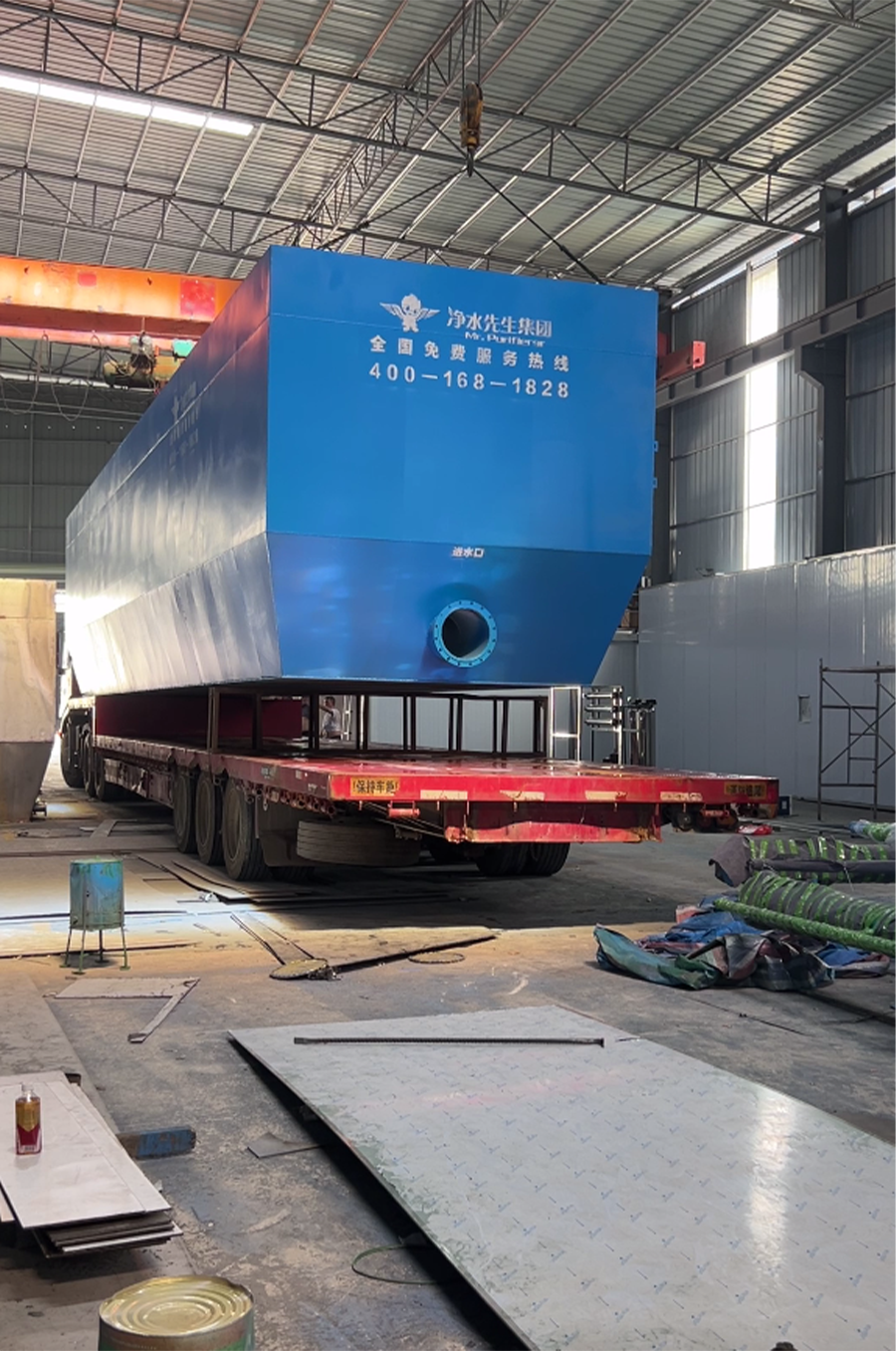

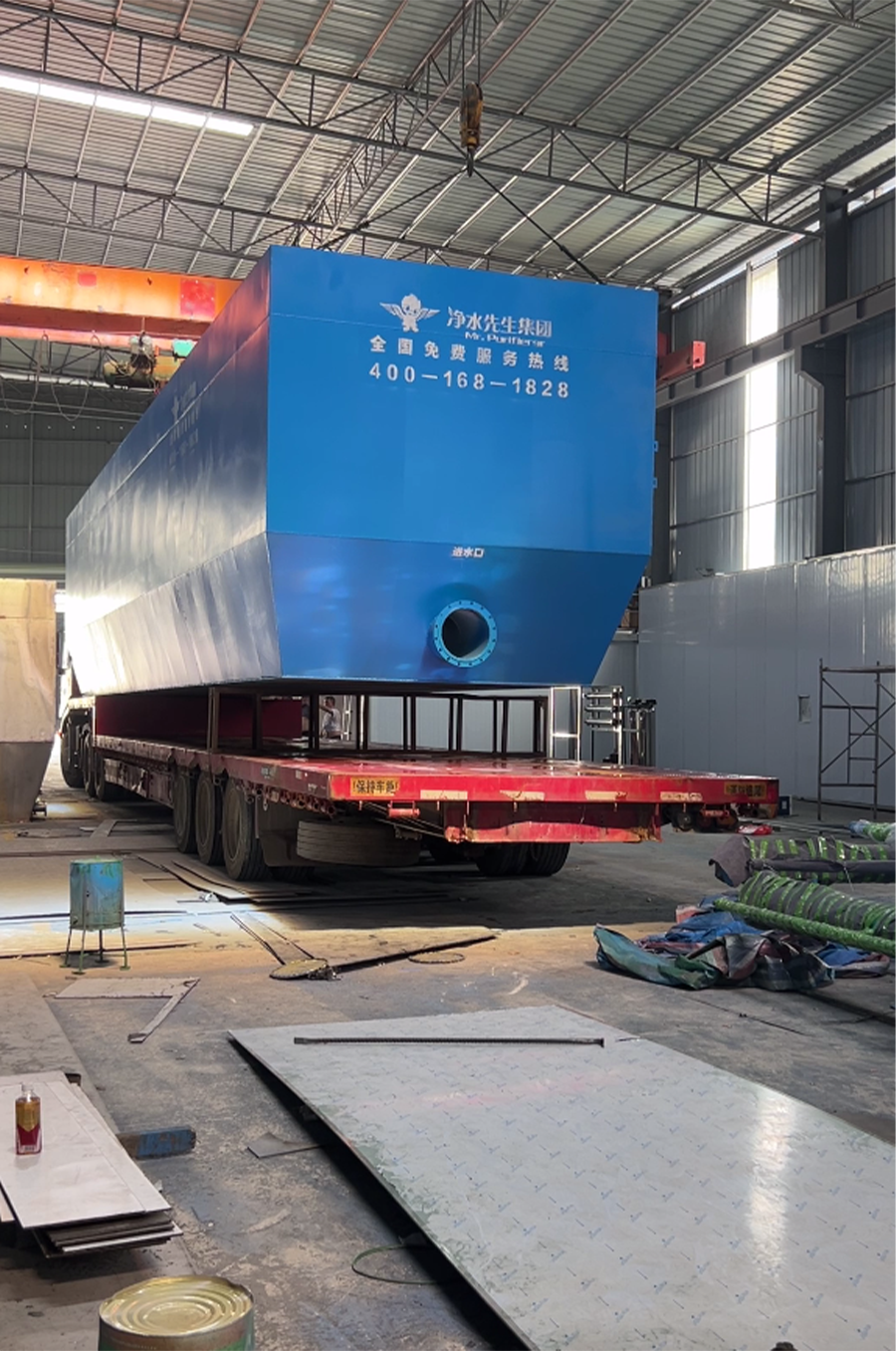

Since 2008, one-third of Dara Sakor's development in Cambodia has been completed, attracting numerous Chinese investors. Dara Sakor is committed to building a comprehensive industrial chain. As a professional manufacturer of integrated water purification equipment, we have been deeply involved in the construction and upgrade of Dara Sakor's large-scale water plant, from refurbishing old equipment to expanding the stainless steel integrated facility to ensure regional water quality. As Dara Sakor continues to develop, demand for water purification equipment will also expand.

The project is located in Koh Kong Province, Cambodia, and its water source is a reservoir formed by the natural confluence of mountain streams and rainwater. The raw water is highly acidic (low pH), and its quality is significantly affected by seasonal rainfall. Turbidity fluctuates dramatically during the rainy season, reaching as high as 3,000 NTU, placing extremely high demands on the stability and adaptability of the water treatment system. Based on field survey results and the client's specific needs, after comprehensive evaluation of multiple options, we ultimately selected a high-performance steel plate structure integrated water purification system as the core solution. The scheme has a designed daily treatment capacity of 5,000 cubic meters. Key process units include:

1. pH Adjustment Zone: For acidic raw water, precise dosing of alkaline agents (such as lime or sodium hydroxide) effectively neutralizes the acidity and adjusts the pH to the optimal coagulation range, while also creating favorable conditions for subsequent processes.

2. Coagulation Reaction Zone: Destabilizes colloidal particles in the water.

3. Flocculation Reaction Zone: Promotes the formation of large, dense alum flocs from destabilized particles, facilitating sedimentation.

4. Sedimentation Zone: Utilizes high-efficiency sedimentation technology (inclined tube/plate sedimentation) to quickly and effectively separate the alum flocs from the water, removing most suspended solids.

5. Filtration Zone: A multi-layer filter media system is configured to deeply capture residual fine particles and significantly reduce turbidity.

6. Sterilization and Disinfection Device: Utilizes highly efficient disinfection methods to thoroughly inactivate pathogenic microorganisms in the water, ensuring the biological safety of the effluent.

7. Intelligent Sewage Discharge and Backwash Device: An integrated automatic control system ensures regular and efficient discharge of settled sludge. Intelligent siphon backwash technology utilizes hydraulic pressure differentials to automatically trigger filter media cleaning, restoring filtration capacity. This eliminates the need for additional power pumps and reduces energy consumption.

Core Advantages and Performance Guarantees:

1. Excellent Shock Load Resistance: Designed specifically for high-turbidity raw water, it can stably treat raw water with turbidity levels up to 3000 NTU.

2. Excellent and Stable Effluent Quality: Effluent turbidity is consistently controlled within 1 NTU, with excellent sensory indicators, fully meeting high-standard drinking water or industrial water requirements.

3. Highly Automated and Intelligent: Equipped with an advanced automatic control system, it fully automates chemical dosing, sewage discharge, and especially siphon backwashing, significantly reducing manual operation and the risk of error.

4. Durable and Low-Maintenance: The steel structure ensures overall rigidity and long-term durability, adaptable to the project environment. Optimized design and automation significantly reduce maintenance frequency and difficulty.

5. Significant Operational Economy: The system design is highly efficient and energy-efficient, with precise chemical dosing and energy-saving siphon backwashing. Overall, the cost per ton of water treated is as low as approximately RMB 0.1, making subsequent operation and maintenance costs highly competitive.

6. Integrated Advantages: All functional modules are highly integrated into a compact structure, occupying a small footprint, making installation easy and shortening the construction period.